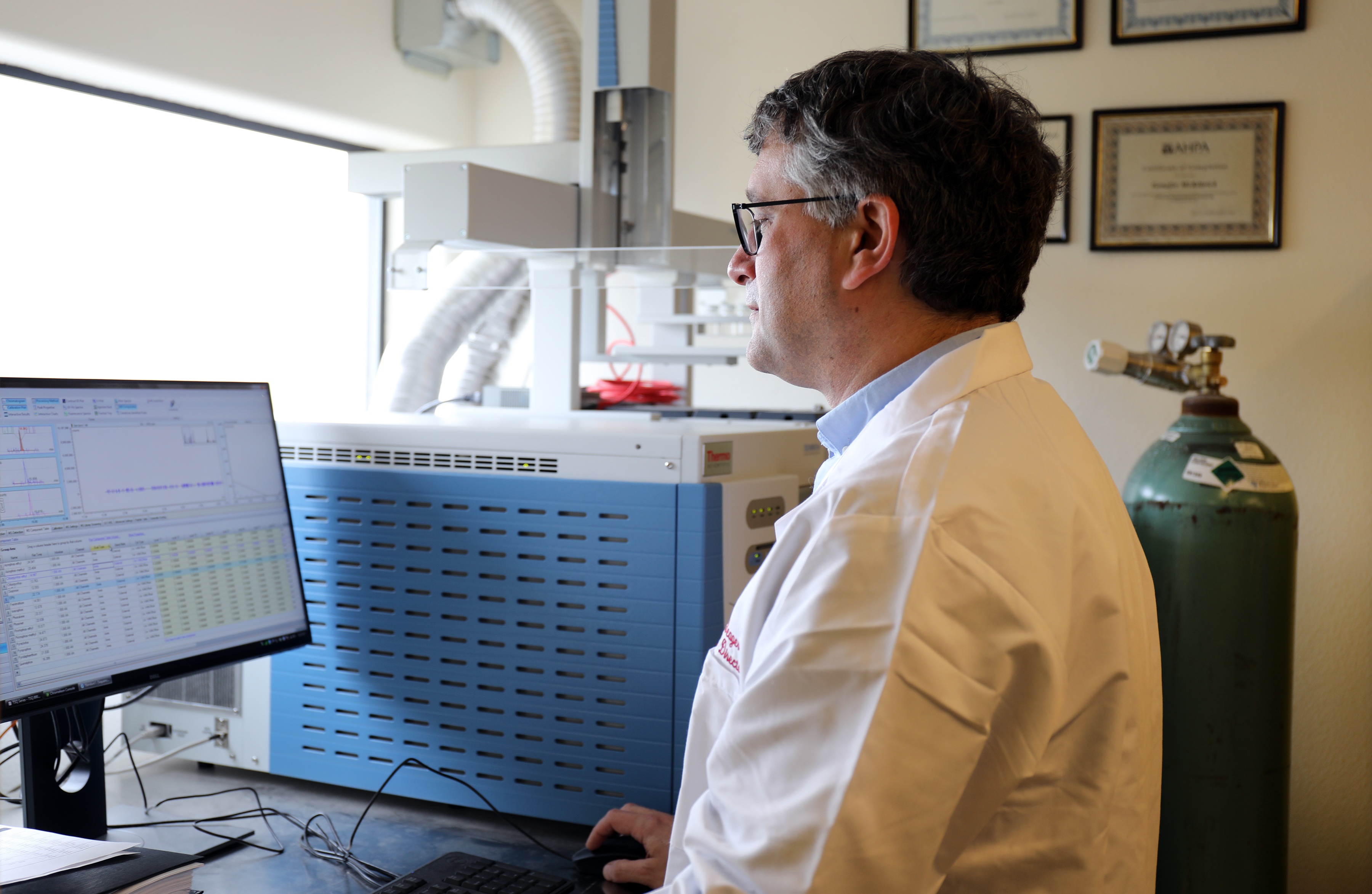

When we ask folks why they choose to buy our botanicals, “quality” typically pops to the top of the list. It’s a proud moment when we realize our relentless search for the best organic botanicals is something you value too. That’s why we sat down with Steven, our Quality Assurance & Quality Control Director, to find out what he and his lab coat-wearing team does behind the closed doors of our in-house lab—the epicenter of quality here at Mountain Rose Herbs.

Q & A with Steven

Mountain Rose Herbs (MRH): Can you tell us a little about who you are and what you do here?

Steven: I’m the Quality Assurance & Quality Control Director, and I have been in this role since 2008. I oversee the laboratory operations, which involves food safety (making sure our ingredients are free from pathogens), and identity testing on our botanicals. I also ensure we’re in compliance with the FDA’s Good Manufacturing Practices for dietary supplements and food products. For supplements, the FDA requires that we perform at least one identity test on every dietary ingredient. In regard to meeting our identity specification, MRH utilizes multiple methods to ensure the correct genus and species is approved for sale to our customers. We perform organoleptic, macroscopy, microscopy, and HPTLC testing here in our laboratory, and on occasion will utilize third party analysis. Performing these assays ensures that not only do we have the correct plant, but also the correct plant part and detection of any adulterants. Since my background is as a trained botanist, this is very import to me and the most enjoyable part of my job! All testing and methods used are reported on a Certificate of Analysis (COA), which is available to all customers upon request. I also have been an Herbal Educator for over 20 years and am co-owner of the Columbines School of Botanical Studies here in Eugene, Oregon.

MRH: Why do you feel quality is so important?

Steven: It’s the foundation of what we do here. Many of us are herbalists, and we refuse to sell products that we wouldn’t want to use ourselves. We expect our products to be safe and effective, and we know our customers do too. A good end product (be it one of our finished products or a botanical a customer might buy for their own creations) relies on starting with high-quality ingredients. There is an old saying: “garbage in equals garbage out”. If you start with inferior ingredients, your finished product or preparations will be inferior too.

MRH: Can you explain the difference between quality and quality control?

Steven: Quality is the end result. Quality control involves setting specifications and implementing procedures that enable us to meet or exceed the quality standards for our ingredients. We set the bar high for ourselves, and as a result our customers expect a lot from us.

MRH: Why do we have an in-house quality control laboratory?

Steven: While it was a big undertaking to fund the laboratory initially over a decade ago, it’s been well worth it and has really reduced our testing costs over time. And lower costs for us mean safe, quality products and a lower price for our customers! Our 4 full-time lab staffers are testing our ingredients on a daily basis to ensure they meet our strict specifications for quality and are free from adulterants and contamination. Also, having the in-house laboratory has allowed my staff and me to have a deeper relationship with the ingredients we offer. We are also well aware of what good quality ingredients should look, smell, and even taste like in many instances. This experience with our ingredients and products increases our quality immensely.

MRH: We’re committed to selling only organic botanicals or offerings that are grown without pesticides. How do you and your team ensure that our products are pesticide-free?

Steven: We only work with growers that are committed to not using chemical pesticides or fertilizers. Before starting a new relationship with an organic grower, we have an approval process which identifies any possible risk of contamination, such as pesticide residues or heavy metal in the farmer’s supply. All ingredients go through a risk assessment process that includes chemical containments such as pesticide residues. If an ingredient is considered to be at risk for this type of contamination it will be tested and the results reported on the lot’s COA.

MRH: Anything new and exciting happening in the lab?

Steven: We’re implementing a new testing technology called Gas Chromatography Mass Spectroscopy (GCMS). This machine will give us the ability to test the identity of our essential oils, which is something we’ve had to solely rely on third-parties to do in the past. By using this technology, we’ll be able to verify that the constituents of the essential oil are within specifications, as well as ensuring there are no adulterants or contaminates. For example, in peppermint essential oil, we look for a specific level of menthol, and that’s one marker of whether it’s a quality product. While we have great relationships with those who craft our essential oils, we still like to make sure we provide the most potent and purest form of the oils possible. We take this a step further, as we want to offer only the best.

MRH: What's your biggest challenge from a quality standpoint? How do we deal with it?

Steven: In my opinion, there is not just one specific challenge, but if I had to pick one challenge, it would be to offer a consistent product from year to year for the size of our customer base. We comply with the FDA’s Good Manufacturing practices for dietary supplements and work daily to comply with these strict requirements. Quality products truly begin with the grower/collector and all of those who we work with are required to adhere to the Good Agricultural and Collection Practices (GA/CP) and ensure they are drying our botanicals at the proper temperature and duration.

MRH: How do we respond to customer questions about the quality of our products?

Steven: Our Quality Control Team monitors all of our customers’ feedback and complaints on a daily basis. We handle all complaints and questions with the utmost diligence and devote a significant amount of time in examining ingredients and processes to rule out any flaws in our products. All information is relayed to our Claims and Returns Team, who relays it to our customers.

MRH: How does our commitment to quality impact the number of products that may be out of stock?

Steven: As customers may have noticed, we have products out of stock from time to time. This is a direct result of our commitment to quality. We’d rather lose business than sell our customers an inferior product. Most of our testing goes unnoticed. Customers just expect a good product, and it’s our job to deliver!

Enjoyed This Peek Into Mountain Rose Herbs?

You may also be interested in: